Suez Engineering Solutions (SES) is a private limited established firm providing innovative and cost-effective solutions to meet your complex engineering, design and operational requirements. We achieve this by combining hands-on experience of the traditional mechanical maintenance techniques with our knowledge across the modern maintenance management technologies across SES platform. Our success is based on this knowledge, our team, and our commitment to SES ethical principles.

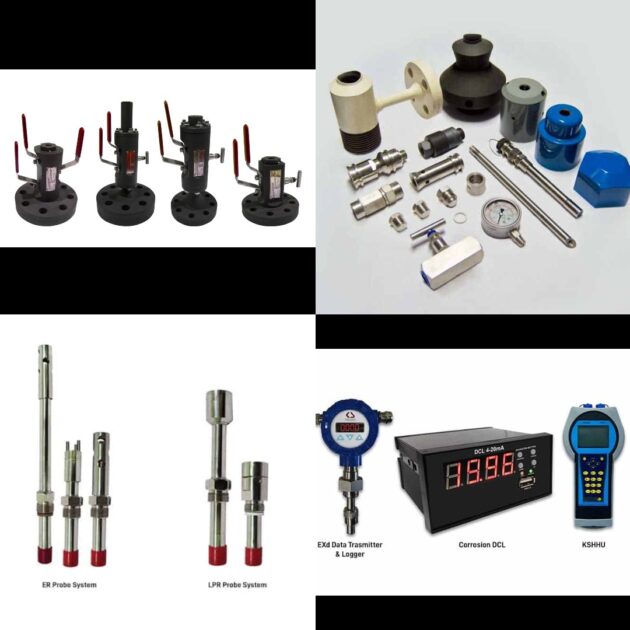

Corrosion Coupon

The Simplest and longest established method of estimating metal loss in pipeline or process plant.

This technique involves the installation of metal coupun into the process line and this coupun is exponsed to process environment for period of time to measure the weight loss of material due to corrosion or erosion.

Corrosion Probe

ER Probe measures the corrosion rate as an increase in electrical resistance over time for a steel probe element exposed to the corrosive environment.

The increase in electrical resistance is proportional to the accumulated corrosion in period exposure. The main benefit of this method is that it can be utilized in continuous on -line process monitoring anf optimize the injection of corrosion inhibitor.

LPR probe measures the direct current throught the metal or fluid interface when the electrodes are polarized by a small electrical potential . As this current is related to the corrosion current that in turn is directly proportional to corrosion rate, the method provides an instantaneous measurement of corrosion rate.

Corrosion Instruments

These products are designed to measure metal loss or corrosion rate from ER & LPR Probe.

The variant products are KSHHU, DCI – Transmitter and DCI-Data Logger.

Connected with PC via Wifi or Bluetooth.

Chemical Injection and Sampling System

Injection and sampling systems are fundamental to corrosion control and mitigation program. Injection system is used for injecting chemical (corrosion or scale inhibitor) treatment.

Meanwhile, the sampling system is used to take a sample of process fluid which is then analyzed in laboratory for determining inhibitor concentration level. the presence of metal ion, oxygen level, etc.

Chemical Injection and Sampling System

Injection and sampling systems are fundamental to corrosion control and mitigation program. Injection system is used for injecting chemical (corrosion or scale inhibitor) treatment.

Meanwhile, the sampling system is used to take a sample of process fluid which is then analyzed in laboratory for determining inhibitor concentration level. the presence of metal ion, oxygen level, etc.

- ANSI/ASME B1.20.1

- ANSI B16 34

- ANSI B16.5

- API 6D

- API 6A

- API 607