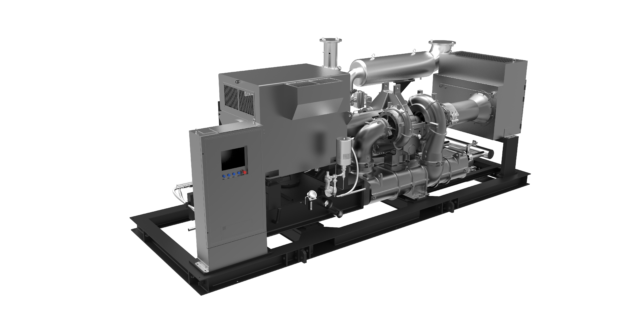

RIVAIR executes complete overhauling of centrifugal and screw compressors both at customer’s site and in our premises.

RIVAIR can provide planned service maintenance contracts with preventive interventions through the most innovative diagnostic check device. Our contracts include technical assistance, periodic checks of the plant and programmed maintenance in order to avoid unpredictable breakdown We are able to make detailed analysis on the status of our valued customer’s compressors with regular checks and test.

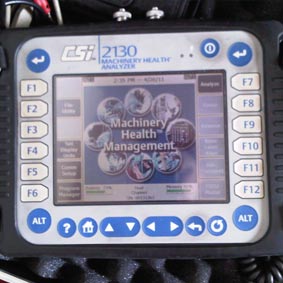

Vibration analysis

We use the innovative “CSI 2140”, a device of last generation. The purpose of the Vibration Analysis is to verify the trend of the compressor and motor rotating parts, where possible, in order to get the performance in acceptable limits.These limits are set by the manufacturer.This job consists of:

To retrieve and record vibration parameters of every single rotor in order to analyze the technical data downloaded during the different running conditions (start up, stop, full load and unload, always where possible).

The vibrations are expressed in micron or mils.

In this case the checked amplitude is the velocity of the vibration into the time (mm/S).

Rivair engineer will deliver to the customer a complete report with operative suggestions and ployts (displacement & velocity)

- Centrifugal air compressor Ingersoll Rand CENTAC

- Centrifugal air compressor Cameron plantair TA

- Engineered Compressor Cameron MSG

- Screw Compressors COMPAIR and INGERSOLL RAND

- Centrifugal Air compressor Compair QUANTIMA